Steps in Manufacturing Partition

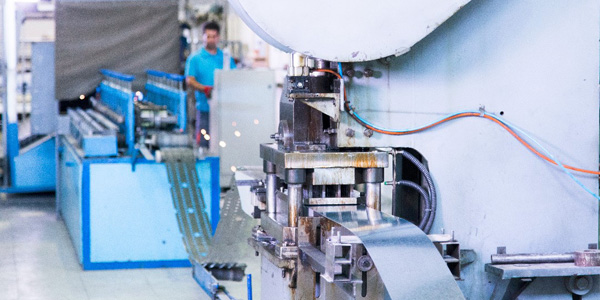

The production of partition in Jalice Company, due to the difference in the raw materials used in this product, is carried out in a completely separate salon from office furniture and with different steps and special machines.

The important feature and difference in Jalice office partition production, compared to other manufacturers, is the metal structure of this product as illustrated in the following pictures:

Roll Forming

The roll forming process is performed by a series of roll forming dies that are installed onto the shafts by bearings. This process is the forming of the metal sheets such as galvanized sheets along the length and parallel of the bending lines of the sheet, carried out by several pairs of rollers at various stations. In short, roll forming is a widely used process of forming all kinds of metal sheets, which has become the best and most efficient method and technology of forming metals in the world during the last half century. Today, up to 45 Percent of all steels produced in the United States are prepared by this process.

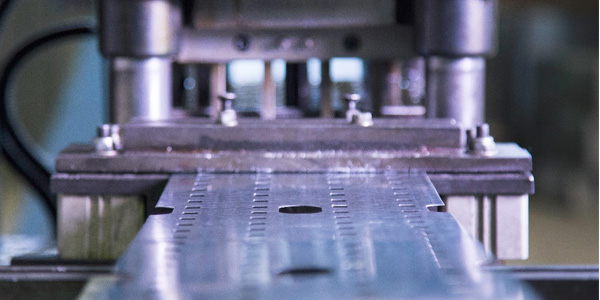

Stamping Press

Stamping press is a metal working tool that can be used specifically to shape or cut the metals. The stamping press by help of a metal hammer (bolster plate) vertically presses the upper part of the mold on the lower part and causes the work piece to be shaped or cut. In general, stamping presses are devices that are specifically used in forming and cutting sheet metal. These machines are designed in such a way that the force, speed and accuracy required to make a piece can be adjusted.

Matrix Molding

Many of the most important industrial parts and tools are made of metal pieces, which are generally made of raw materials and raw sheets with different thicknesses and very high accuracy. To produce these products in high circulations and uniform accuracy and quality, the matrix metal molds are used. These types of molds are considered as one of the most important, practical, affordable and accurate equipment for the production of metal supplies, in all of which cutting or shaping is done by two parts, the punch (male) and the matrix (female).