Company Information

We provide the best choices for your convenience. Experience a convenient life with Jalice.

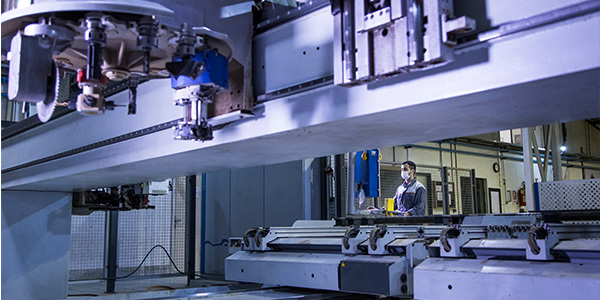

More than three decades of delivering the highest quality of products to customers have led Jalice to be one of the most trusted brands in the office furniture industry in the Middle-East. Currently operating at a 15,000 square meter state of the arts manufacturing facility, Jalice offers a range of office furnishing solutions, from the modest administrative desks to complicated modern partition wall systems.

Starting from its very first product, a simple computer desk, in 1974 until now, customer’s needs and satisfaction has always been the main focus and drive behind every decision that takes place in the company. Jalice office furnishing group will continue to hold itself to the highest standards and will insure to use innovation and latest technologies to technologies to keeps its brand synonymous with quality and trust.

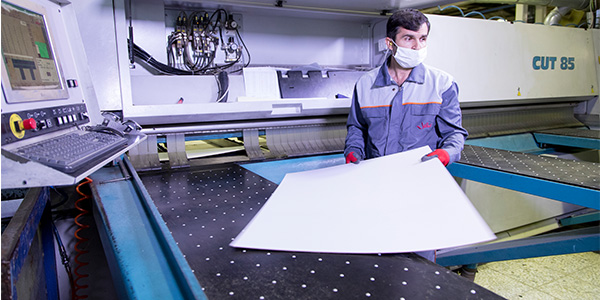

Jalice Production Process

It is obvious that the production process of each product is defined according to its design and function. Still considering the case, the production process of a product in Jalice factory can be summarized as follows:

Jalice Clients

Jalice Industrial Group Achievements